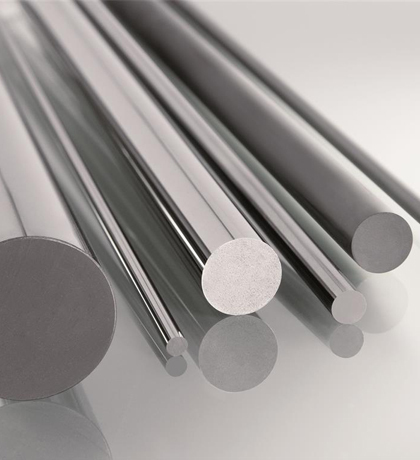

Solid tungsten carbide rods have become an essential resource for modern tooling solutions. Their unique combination of strength, durability, and versatility makes them stand out among materials used in industrial applications. From maximizing tool life to offering unmatched precision in various machining tasks, it's no surprise that they are one of the most sought-after materials for manufacturers worldwide. This post will explore why solid tungsten carbide rods are a preferred choice for tooling, how they compare with alternative materials, and their impact on industries such as milling, drilling, and reaming.

Table of contents:

Maximizing Tool Life and Efficiency With Tungsten Carbide Rods

Comparing Tungsten Carbide to Alternative Materials in Tool Production

Exploring the Versatility of Rods for Milling, Drilling, and Reaming

How Tungsten Carbide Enhances Precision in Industrial Applications

Maximizing Tool Life and Efficiency With Tungsten Carbide Rods

Manufacturers and tooling specialists highly value solid tungsten carbide rods for their exceptional tool life and efficiency. Tungsten carbide, a composite of tungsten and carbon, is renowned for its hardness, high melting point, and resistance to wear and deformation. Tools crafted from tungsten carbide rods maintain their sharpness and cutting edge for extended periods, reducing the need for frequent replacements or maintenance. This durability translates into lower operational costs and minimizes downtime, making it an attractive option for businesses aiming to improve productivity. Additionally, tungsten carbide rods can consistently handle high-speed machining operations without compromising performance, making them ideal for cutting, milling, drilling, and other machining applications. When sourcing durable and high-performing materials, working with reputable tungsten carbide rods suppliers is essential to ensure quality and reliability.

Comparing Tungsten Carbide to Alternative Materials in Tool Production

When it comes to tool production, tungsten carbide rods have a significant edge over other materials like steel, high-speed steel (HSS), or even ceramics. While steel tools are more economical, they are prone to quicker wear and lack the strength needed for precision tasks under harsh conditions. High-speed steel is a step up, offering better heat resistance, but it still lags behind tungsten carbide in hardness and overall performance. Ceramics, often used for industrial tooling, offer excellent heat resistance but are brittle and susceptible to fractures under pressure. Solid tungsten carbide rods bridge all these gaps—they excel in wear resistance, handle high temperatures without losing strength, and can endure heavy loads without fracturing. The versatility and resilience of tungsten carbide make it a prime choice for tools requiring high precision and durability across various industries.

Exploring the Versatility of Rods for Milling, Drilling, and Reaming

One of the key advantages of solid tungsten carbide rods is their versatility. These rods are extensively used in processes like milling, drilling, and reaming—essential operations in industries such as manufacturing, automotive, and aerospace. For milling, tungsten carbide rods deliver smooth operations by maintaining consistent cutting precision, even with high-speed spindles. Drilling operations benefit from their rigidity, as they minimize tool deflection and ensure clean, accurate holes even in tough materials like stainless steel or titanium. For reaming, an application requiring precision finishing of holes, tungsten carbide rods provide excellent dimensional accuracy and surface finish. The versatility of tungsten carbide rods stems from their ability to withstand intense pressure and maintain structural integrity across a wide range of applications. Hence, partnering with a trusted tungsten carbide rods supplier can open doors to a multitude of machining possibilities for businesses.

How Tungsten Carbide Enhances Precision in Industrial Applications

Precision is paramount in industrial applications, whether you are producing automotive components, aerospace parts, or high-end electronics. Solid tungsten carbide rods play a pivotal role in delivering the accuracy that industries demand. Their hardness and strength minimize tool wear, ensuring consistent performance over extended usage. This reliability directly translates into precise, repeatable machining results that are critical for tight tolerances. Furthermore, tungsten carbide minimizes vibrations generated during machining, reducing errors and surface roughness in finished products. For industries where accuracy is a non-negotiable factor, such as aerospace and medical device manufacturing, tools made from tungsten carbide rods are indispensable. Leading tungsten carbide rods suppliers understand this requirement and provide customized solutions to meet the unique needs of various industrial applications.

Tungsten carbide rods have revolutionized industrial machining by offering unparalleled durability, accuracy, and reliability. Their exceptional properties, such as extreme hardness and resistance to wear, make them an essential choice for industries where precision is critical. From reducing tool maintenance costs to achieving flawless machining results, tungsten carbide continues to be a driving force behind advancements in modern manufacturing. By partnering with trusted suppliers, industries can unlock the full potential of tungsten carbide solutions, ensuring consistent performance and meeting the highest standards of quality in production.

Comments

Post a Comment